Ultrasonic waves (acoustic waves with a frequency greater than 20 kHz) have strong penetrating capabilities. Ultrasonic testing equipment is simple, easy to use, and has good safety. It is widely used in pipeline nondestructive testing.

The most commonly used ultrasonic testing method is the pulse reflection method. The principle is that the transmitting circuit emits high-frequency electrical pulses, which are added to the transmitting receiver (that is, the probe), and the ultrasonic pulse generated by the probe is incident on the material to be measured. The echo reflected by the defect and the bottom surface is received by the transmitting receiver. In the case of dual probes, the transmission and reception are separated and the echo is received by the receiving probe.

The probe converts the ultrasonic pulse into an electric pulse, which can be input into the display device or computer for observation and processing after being amplified and conditioned by the receiving circuit. The T wave, F wave, and B wave displayed by the CRT are the initial wave, the bottom wave, and the injury wave, respectively. According to the position of the injury wave B on the time axis, the distance of the defect from the surface can be determined, and the amplitude of the injury wave is related to the depth, shape and nature of the defect.

The probe is a component that directly contacts the test piece, and is also a key component for generating ultrasonic waves and receiving echo signals. The ultrasonic part of the developed submarine pipeline inspection device has a total of seventy probes, arranged in seven circles, with ten probes in each circle evenly distributed along the circumferential direction.

During the test, each tested area in the pipeline will be tested by 7 different ultrasonic sensors in sequence. The data measured by the 7 sensors is input into the neural network for data fusion to obtain the desired output.

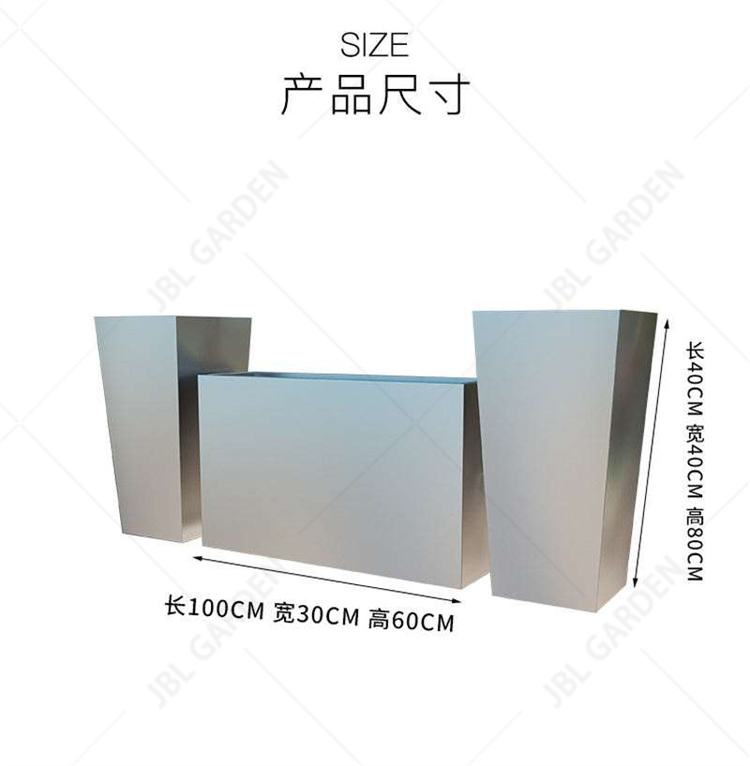

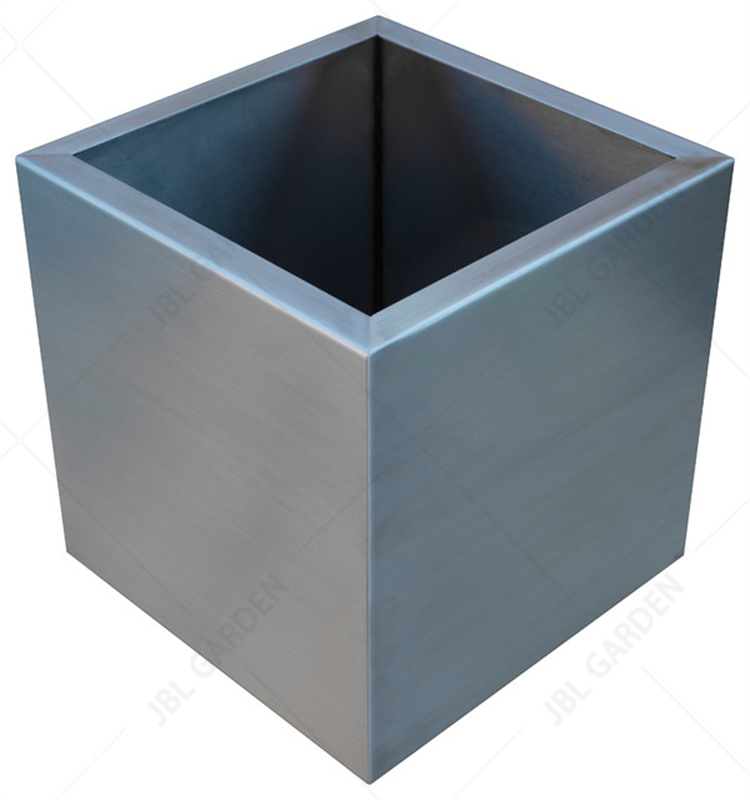

Stainless Steel Flower Planter

Great way to bring the outdoors into your space. Plant pots are perfect for growing succulents, grass, and small plants.

Contemporary Industrial Style - Stainless steel Flower Planter fits into any home décor with the simple shape and stainless steel material.

Included (4) low profile rubber pads - Easy to install, provides increased stability, and protects metal plant pots and the surface that you place it on.

The Stainless Steel garden pots helps you bring home a clean and sleek designer look. Perfect on the window sill, counter top, Fireplace mantle, and as a table's centerpiece. The heavy duty stainless steel is hand welded to ensure a water tight enclosure.

* EASY TO CLEAN: Like most stainless steel, finger prints and water spots may show. Simply use a damp towel, or a little window cleaner will take care of it. The plants depicted in the picture are not included with the purchase.

We also offer other steel materials,like Corten Steel Flower Planter,galvanized steel flower pots.

Stainless Steel Flower Planter,Garden Plant Pots,Flower Pot Holder,Metal Plant Pots

Henan Jinbailai Industrial Co.,Ltd , https://www.hnjblgrill.com